I spent my weekends growing up in the garage with my dad while he was building furniture. Somehow, up until this weekend, I've managed to never use an electric saw or nail gun. But yesterday I decided to break them both out of their packages and complete not one, but two wood framing projects simultaneously, despite my lack of knowledge/experience. How hard could it be.... right? Well the answer is, not entirely, you just need to follow a few rules that I found out the hard way. Here's what went down, and the lessons I learned (after over 40 miles of hardware store trips).

Framing a MapI had purchased a large wall map a couple months back on Amazon that I thought would be perfect in the office. The poster paper on the wall look was a bit too unfinished for my liking, so I decided I would frame it in with crisp white trim and mitered edges.

The first step, of course, was measuring. So I took my measurements (70" long by 48" tall), and went to Home Depot to find some trim. The trim had to be flush against the wall on both edges, so crown molding was out. I settled on some lovely corrugated-type trim (sorry, I forgot the technical term) that I thought would bring a bit of interest to the piece. I made the rough cuts at Home Depot and brought it all home.

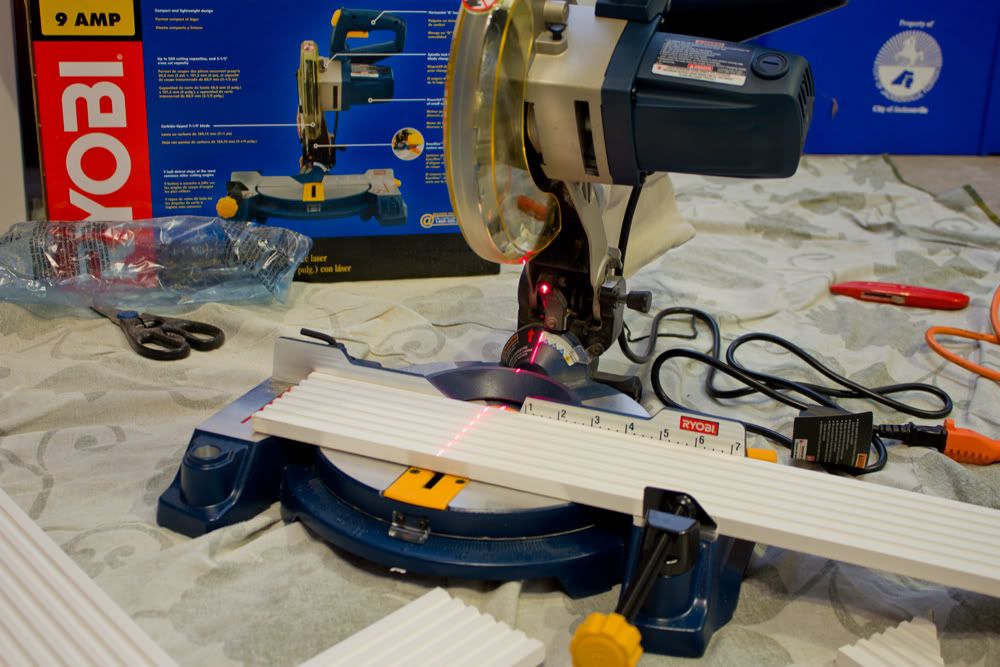

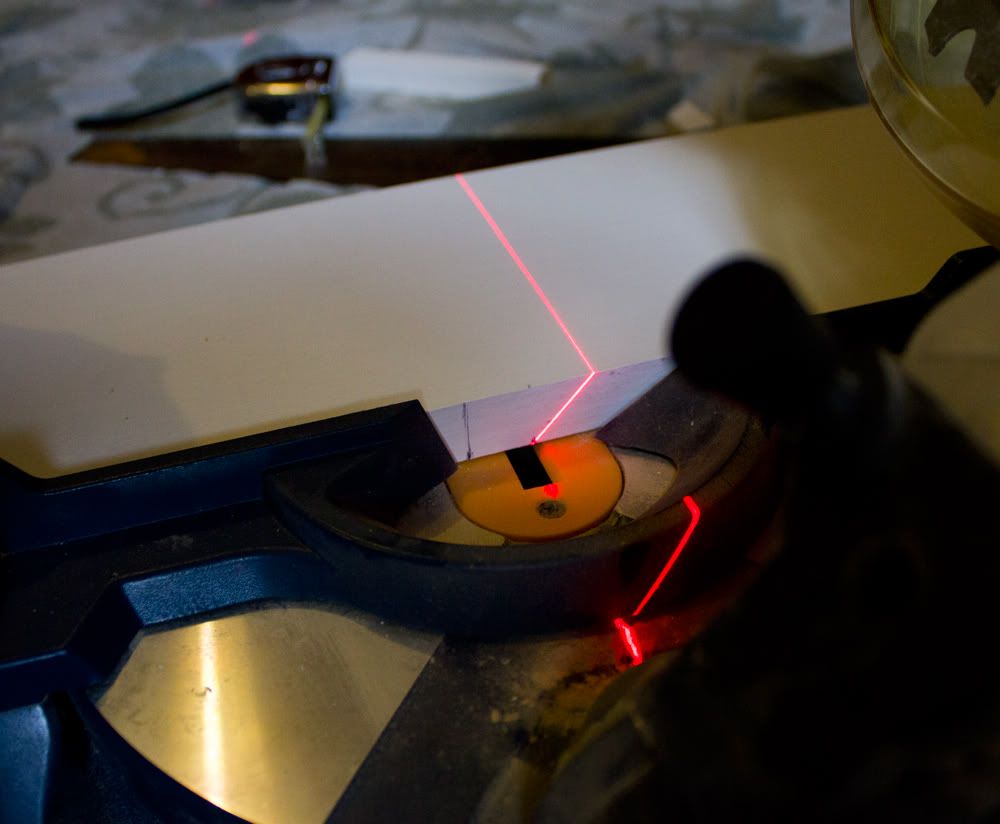

Here's our lovely saw in action:

Can I just stop for a minute and tell you how necessary this laser is? I can't believe some saws come without it, there's no possible way we could have made an accurate cut without it. Moving along...

After making my first cut, I immediately realized that I forgot to account for the extra length needed when making 45 degree cuts, which brings me to my first lesson:

1. Measure, measure again, then measure again, then stop for a minute and look at what you're about to do, and measure again.

There's one piece of board ruined. At that point I weighed my options, and decided it might be a better idea to just make straight easy cuts and use rosette blocks in each corner (which Brad had originally suggested in the store, but I declined). Of course, that required another trip to Home Depot, so off I went for trip #2. They only had two blocks left, so I had to drive down to Lowe's to find four in the correct size.

Back at home, we finished off all the cuts (after some trial and error, realizing that the saw wasn't set exactly to 0 degrees, thus making slightly crooked cuts), and we migrated to the office to try and figure out how to adhere the map to the wall. It was currently secured by eight tacks, and Brad suggested using hot glue on the edges. We had nothing else, so hot glue it was. This seemed to work okay, until we somehow ended up with air bubbles once it was all sealed. Too late now... maybe the trim will cover it?

We worked our way around the map, starting from one edge to the other, using the nail gun to secure the trim into the wall. We used hot glue on the rosettes as not to damage them with the nails (since we couldn't get them flush against the trim due to the divets). That worked fine. Somewhere along the way we realized either the trim or the map was crooked, because the border was not even along the edges. But at this point we had given up and were rushing just to get done. (Sorry, this is why there are limited pictures of the actual construction).

At this point, Brad went and partied while I stayed and caulked every edge and re-painted everything. For our very first miter saw/nail gun project, I'll say it was only slightly disastrous. Here's the finished result:

Here's the edge detail up close:

All in all, I'm glad we decided (not by choice) to go with the rosette corners. I think it adds a touch of sophistication, and definitely turned out better than my crooked miter cuts would have been.

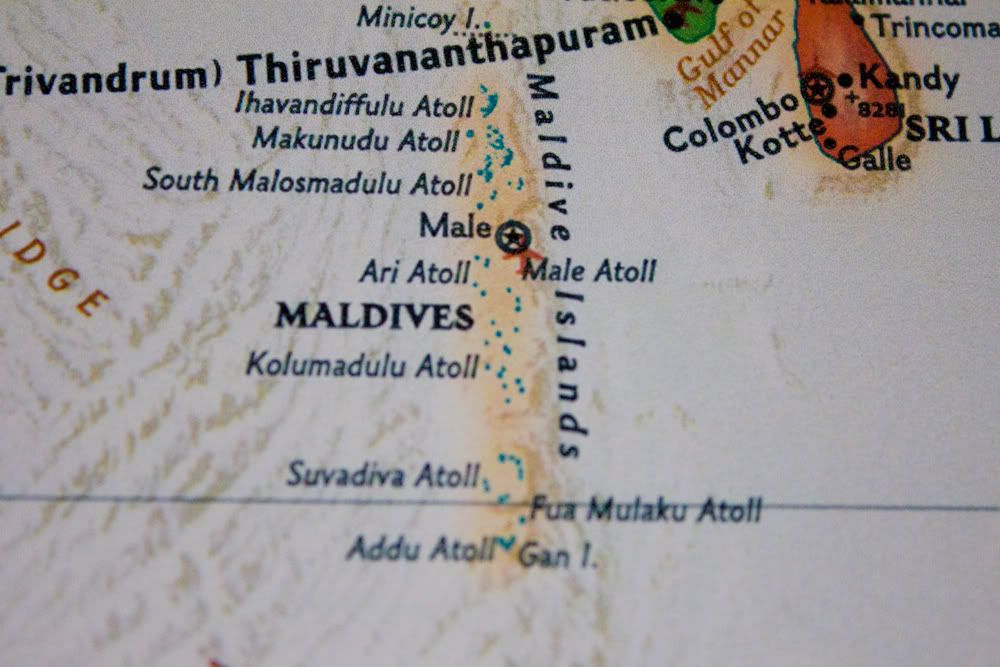

But really (and Brad doesn't know this yet), I just bought it so I can see all of my future private island investments up close and start planning out my yacht routes, like here...

maybe a couple in here,

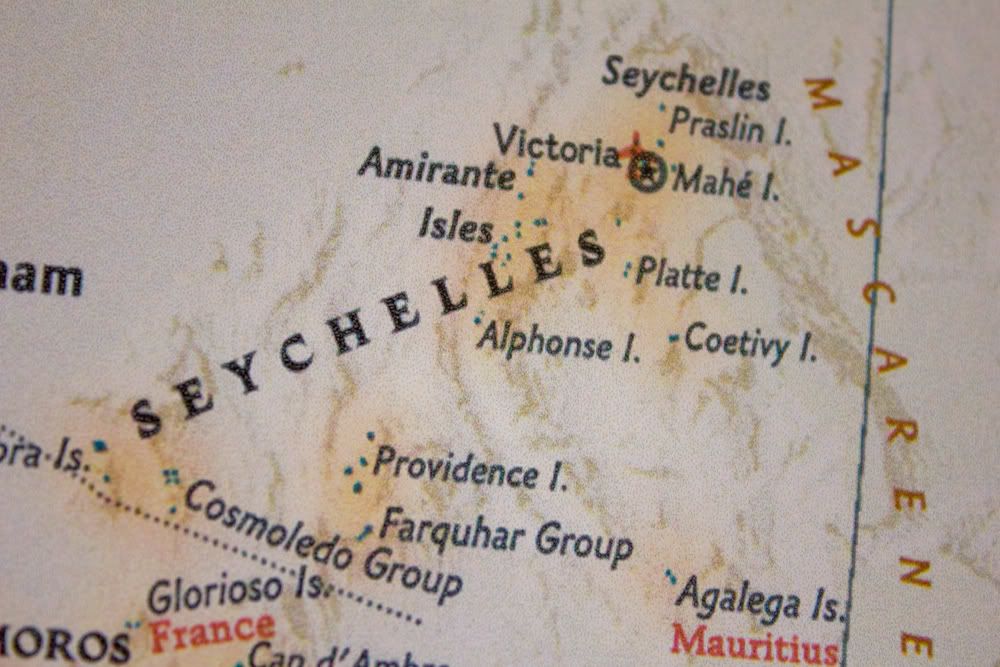

and for sure one of these blue dots will have my name on it...

...someday.

Anyway, onto our project #2...

Building a Coat Rack

This one I've been scheming about since the day I moved in and saw that lonely, empty foyer wall. It was just begging for a coat rack. So today I granted its' wish... but not after some serious struggles.

I had originally pictured a standard 2x4" board for this, but of course Home Depot didn't carry such a size in a primed finish (limited time, didn't want to deal with bare wood). So I went for the closest thing, which was 1x6" primed pressboard/MDF. $9 for about an 8 ft piece, perfect.

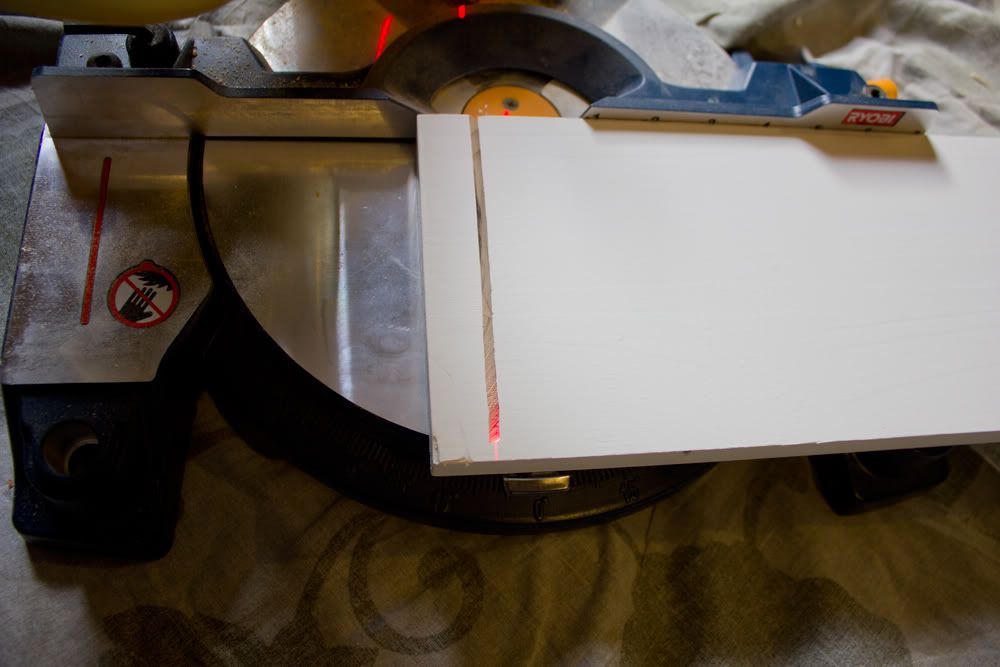

We get home, take all the measurements, get ready to make the cut... and this is what happens:

Great... our saw is too small. Which brings me to the next lesson of the weekend:

2. Use the correct tools for the job.

I never imagined having the need to cut wider than 4" when I purchased the saw, but you never know... and this is what I get. So brad took a hacksaw to it to try and finish it off, which resulted in this edge:

And this was the smoothest edge of the day by a long shot.

But that became trivial as soon as I realized I had cut the wrong angle. Crap... another board ruined. I tried to conjure up ways to somehow fill the gap... but this was just not about to happen:

Off to Home Depot/Lowes again. This time I went to a different (ahem, closer) HD location, but of course they didn't have that same board. So I bought a 1x8" pine (not pressboard) wood for about the same cost. Which brings me to my next hard-learned lesson:

3. MDF > Real wood... at least when it comes to ease of cutting.

Making the saw-cuts by hand on MDF was a piece of cake compared to pine. That thing splintered and broke off like no other. We spent about 30 mins with a utility knife and sandpaper trying to smooth the angle down to fit. But this time I took half the morning to walk back and forth from the foyer to the garage to make sure the angle was right so I didn't screw it up yet again. Brad (the genius he is) pointed out that the laser actually showed the line of the angle cut, which made my life 100x easier:

So we finally cut the dang thing, but we couldn't saw the straggly edge off straight. I nearly gave up at one point, about to return the saw to get a larger one just so I could make a smooth cut. But my sanding paid off, and the dang thing finally went into place.

|

| I later fixed this edge with sanding, caulk and spackle |

|

| I filled and smoothed this edge, too |

Finally, success! Now to mount the dang thing. We knew we wanted the screws to be hidden, so the obvious place would be to mount them behind the hooks. But of course we needed to be on the studs, and we had no stud finder... so we went with the drywall inserts instead. I bought five hooks, so I measured the spacing from one end to the other and made my marks. We then drilled pilot holes for each, and held the board up to the wall to go back through the holes. Luckily, the far right hole happened to land in a stud, so we decided to just use one more drywall insert in the middle, and one on the end.

We counter-sunk those three holes so we could mount the hooks flush over them (the other two holes in the middle we just left as is, as they were no longer needed).

With the board finally sturdy, I used our laser-aligner and made my marks just below each hole for the hook screws. Worked like a charm, and here they are all lined up (with the proud hubby)

Here's a good before shot of the foyer. The coat rack was installed on the right (I posted the After shot of the left side in last week's post):

|

| Before |

Whew, so glad that's over! And proud for being able to pull it off, despite the lack of tools/knowledge.

Now here's the fun stuff. My storage bench from Target arrived!

Isn't she lovely? I love that it maches our room so perfectly... turquoise & cream. Yum. And she's not just pretty to look at, she's functional too:

Not that I even have anything to put in there... I'm just in love with storage of any kind. Living in a 700sq ft house for 2 years will do that to you.

How sweet is this fabric though?

And now, I'm proud to say, we have our first complete wall of the entire house:

This is the wall opposite our bed in the master. Last week, we had just wall-mounted the TV and were trying to figure out a storage solution for the cable box. I was originally going to fabricate some small floating shelf just underneath it (yeah right, after barely being able to install a coat rack), but we realized that the box might just be small enough to hide between the wall and the TV. What a perfect plan that would have been.... if we had mounted our outlet like 4 inches over. Ugh, bummer. It was too late to move it, so we went with the second best option, sliding it as far down as we could behind the TV until it hit the wall mount. You can see it poking up there above it. Really, it doesn't look bad at all... you could mistake it for part of the TV. And from lower angles you can't even see it at all:

Hey, works for me.

In a word, I feel accomplished this weekend. I now know what I can and can't cut, and I think I'll make a lot less mistakes from here on out. Almost ready to tackle the chair rail & molding in the dining room. Let's see what happens next week!